Properties / variants

Up to approx. 500 m³/h | |

Screw conveyors | Up to 40 m |

Materials | In stainless steel, regular steel, and special materials such as wear-, chemical-, and temperature-resistant materials |

| Trough shapes | Pipe trough, U-trough, V-trough, omega trough, double-U trough |

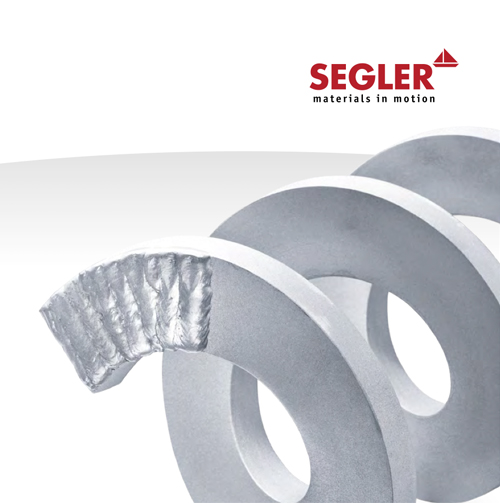

| Design | Variable blade and shaft design: Conical helix, changing, progressive screw gradient, ribbon spiral, toothed etc. (-> Link to page "Auger shafts and auger blades") |

| Configurations | Hard facing, wear protection plates, coatings, cleaning openings, inspection hatches, RPM monitor, fill level detector, CIP, multiple goods loading/dispensation points. |

| Variants | Dust-proof, gas-tight, pressure-tight and/or shock pressure resistant, vacuum operation, food safe, ATEX-compliant, WGH-compliant (water protection) |

| Seals | Product-specific seals |