Properties / variants

Up to 30m³ | |

Materials | In stainless steel, regular steel, and special materials |

| Trough shapes | Casing pipe, U-trough, omega trough, double-U trough, cone with torispherical head |

| Mixing principles | In turbulent area/mechanically generated fluidized bed, in pile |

| Mixing tools | Single helix, double helix, (conical) mixing shaft, cutter heads, lateral scrapers, special blades (link: Auger shafts and blades), paddles, blade paddles |

| Configurations | Hard facing, plating of mixer shaft, wear production cladding of housing, additional cooling/heating jacket, thermo blades, CIP, feed hopper, spraying devices, electrically or pneumatically operated discharge flaps, inspection openings, special outlet ports |

| Variants | Food safe, ATEX-compliant, WHG-compliant (water protection); heavy duty, dust-proof and gas-tight, explosion pressure resistant, pressurized operation, vacuum operation |

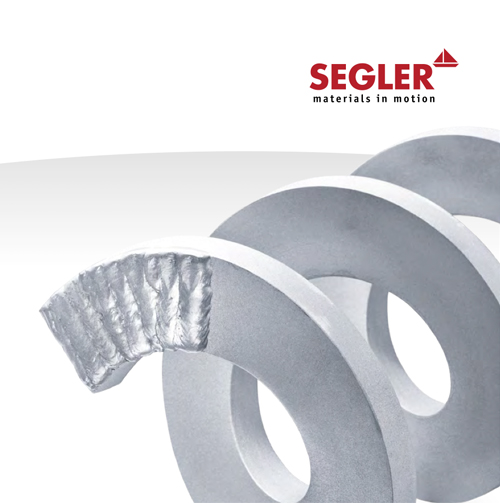

| Seals | Product-specific seals |

| Service life | Continuous operation |

| As required | Where required, specially configured metering, cut-off and discharge devices |

Advantages

- Reproducible product quality

- Optimal product flow with short mixing times

- As required: from gentle product homogenization to increased shear forces acting on product to the integration of additional process steps

- Good accessibility, allows for optimal cleaning

- Increased service life with maximum system availability

- Solid design for high user-friendliness and minimization of problems

- Long service life

- High availability