Our employees are masters of their craft. Thanks to their commitment and often many years of service at SEGLER, we possess extraordinarily in-depth technical expertise. This experience and know-how, e.g. in metal processing and for working with conventional as well as special materials, is incorporated into their work. At the same time, we also greatly emphasize excellent training and further education for our staff.

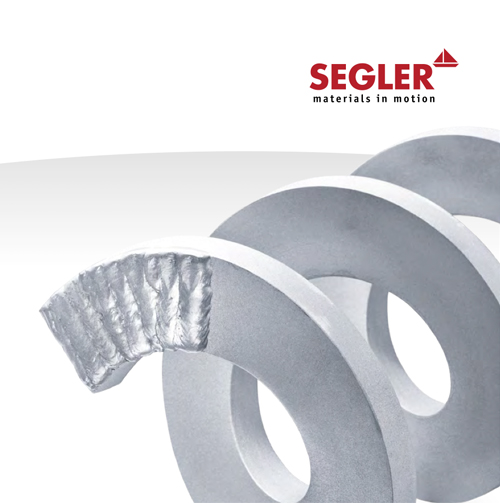

Welding work is performed exclusively by qualified, certified specialists

utilizing the very latest processes, of course.

Technical equipment

- 3D CAD design software Solid Works

- CNC processing center (turning and milling)

- Assembly hall with gantry crane; supports 2 x 16t loads at a working height of 6 meters

- Laser cutting system for up to 12 mm stainless steel

- Plasma cutting system (fine plasma) for up to 60 mm stainless steel and rotator for pipe and torispherical processing

- Grinders

- CNC bending center with 640 tons pressing force to 6 meters length

- Various blade presses, rollers, saws

- Welding

- WIG, MIG/MAG, PTA

- Welding robots with laser weld search system

- Hard facing with various flux-cored wires made of tungsten carbide (also pipes from inside along a length of up to 6 meters)

- Surface technology

- Painting hall for coatings

- Pickling and neutralization installation for stainless steel

- Separate blasting installation for stainless and regular steel